Objectives

MEMBER aims to demonstrate currently state-of-the-art capture technologies in industrially relevant environment. To achieve this, MEMBER will scale-up and manufacture advanced materials and will prove their added value in terms of sustainability and performance under industrially relevant conditions (TRL 6) in novel membrane based technologies that outperform current technologies for pre- and post-combustion CO2 capture in power plants as well as H2 generation with integrated CO2 capture and meet the targets of the European SET plan.

MEMBER will address the following issues:

- Increase the manufacturing readiness level (from MRL 4-5 to MRL 6) of a portfolio of materials for the production of Mixed Matrix Membranes for pre- and post-combustion CO2 capture in power plants (H2/CO2 and N2/CO2 separation).

- Increase the manufacturing readiness level (from MRL 4-5 to MRL 6) of hydrogen membranes, reforming catalysts and CO2 sorbents materials, and integrating them into an advanced Membrane Assisted Sorption Enhanced Reforming (MA-SER) process for pure H2 production with CO2 capture.

- Develop a software tool to simulate MEMBER components, the processes and CO2 capture energy performance.

- Design and construct 3 prototypes for CO2 capture for testing of the developed materials in relevant operating conditions at TRL6.

- Demonstrate the MEMBER systems and related business models in 3 representative demonstration sites across Europe, covering different sectors, membrane based technologies and CO2 containing streams

- Prototype A, targeted for pre-combustion capture in power plants using MMMs at the 2MWth biomass gasifier of CENER (Spain) aimed for BIO-CCS demonstration.

- Prototype B targeted for post-combustion capture in power plants using MMM at the 8.8MW CHP facilities of Agroger (GALP, Portugal).

- Prototype C targeted for pure hydrogen production with integrated CO2 capture using MA-SER at the IFE-HyNor Hydrogen Technology Centre (ZEG Power, Norway).

- Quantify the environmental impacts of the proposed holistic solutions through life cycle assessment.

- The exploitation of the results including the definition of a targeted and quantified development roadmap to bring the technologies to the market.

- Overcome CCS market barriers with an ambitious set of CCS solutions.

Work plan

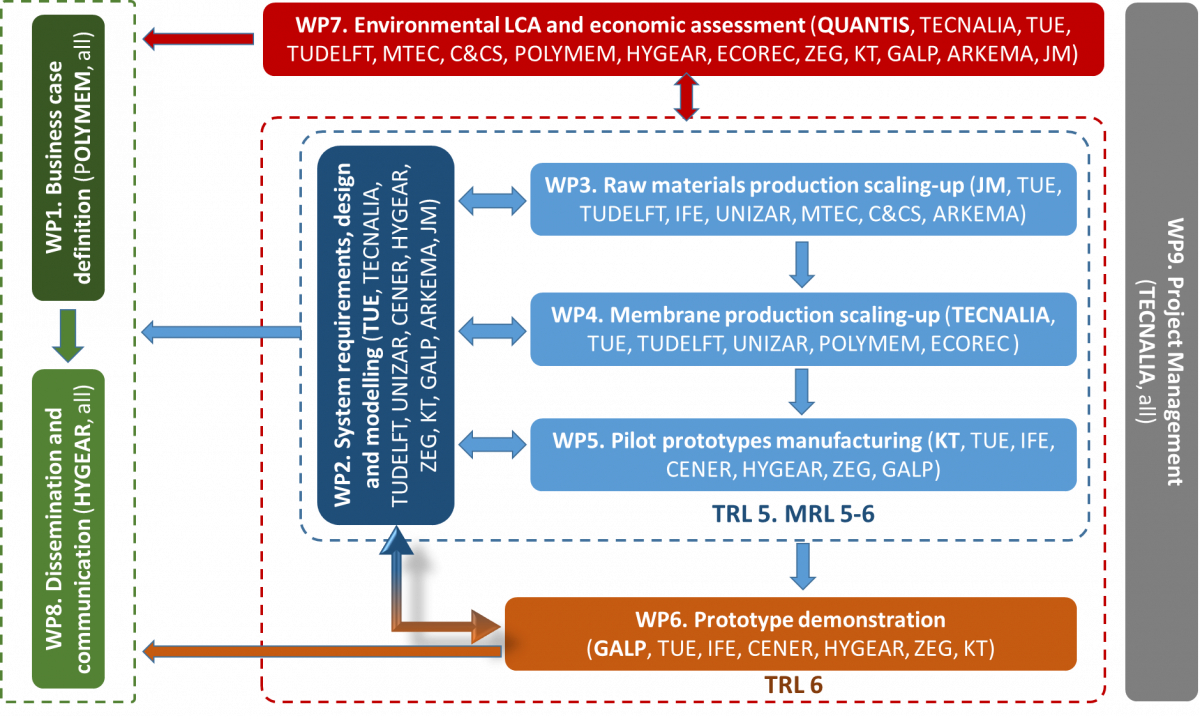

The MEMBER project structure is subdivided in10 work packages following the focus on the development of the CO2 capture processes. Furthermore, the project will demonstrate the capture technologies in industrially relevant environment. Therefore, the work structure is based on the following work packages:

WP1 is aimed to an early business case definition, clear understanding of market barriers and needs, regulatory framework and potential risks. The final objective is to guide the project towards highly deployable results, fulfilling the needs of the target market. WP1 also sets the framework for high impact dissemination actions to promote and support future market uptake. WP1 starts in month 1 and goes through the whole project. In parallel, WP2 translates the general framework established in WP1 into a coherent set of specifications for the membrane based CO2 capture systems that will be demonstrated within the project as well as defining the requirements of the different materials and their scale up. These specifications must be in accordance with every business model defined in WP1 and will gather the inputs from the end-users and demonstration site owners of MEMBER. In addition, WP2 will gather all the modeling related to membrane and system modeling as well as the final system design performed.

WP3 targets to scale-up the production processes of the core materials employed in MEMBER. In this WP, optimisation of best performing materials, their scale up, recyclability and economic evaluation at industrial scale will be performed. The materials produced will be delivered in WP4 and WP5.

WP4 will tackle the production of the membranes for the three CO2 capture prototypes developed in MEMBER that will be later integrated into the pilot prototypes constructed in WP5.

In WP5 all the different materials (membranes, sorbents and catalyst) and balance of plant components will be integrated into the three different prototypes constructed for demonstrating and validating the performance of the materials and associated processes.

WP6 will be focused on the demonstration at TRL 6 of the three CO2 capture systems developed in MEMBER, each of them being located at different relevant demonstration sites.

In WP7, LCA, LCC and techno-economic assessment will be performed, in order to prove the viability of the developed materials and technologies, and to give insights about the further use of the technologies.

The results of WP6 and WP7 will directly feed into the definition of business cases in WP1, dissemination activities WP8, optimisation processes (WP2) and further optimization of technical solutions (post-project) to pave the way towards market uptake.

WP8 runs throughout the whole project, feeding from the results of previous work packages, and providing support to exploitation of project results through highly focused communication and dissemination activities.

WP9 ensures an effective project management all along the execution of the work plan. And, finally, WP10 will address ethical requirements including Environment, Health and Safety.

The key milestones in the frame of the project are:

- design of the three CO2 capture concepts at month 26

- availability of the prototypes at month 36

- demonstration of the prototypes at month 48